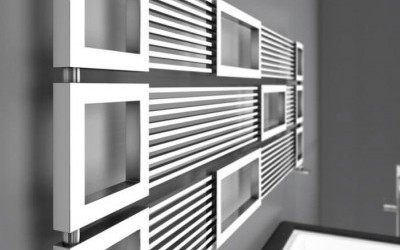

Custom towel warmers manufacturing

Custom towel warmers manufacturing is the process of creating individual and functional devices designed for heating and drying towels and clothing in bathrooms or other spaces. Towel warmers can be crafted in various styles and sizes to meet specific needs and interior design preferences. Here are several key aspects of custom towel warmer manufacturing:

-

Design and Consultation: The process starts with a consultation with the client to determine requirements and preferences for the future towel warmer. Factors such as size, shape, style, materials, and specifications are discussed.

-

Material Selection: One of the crucial aspects is the choice of materials for manufacturing. This can include stainless steel, aluminum, copper, or other materials that provide durability and heat conductivity.

-

Fabrication and Processing: After selecting materials, the towel warmer manufacturing process begins. This involves processes like cutting, welding, bending, surface treatment, and other techniques.

-

Installation and Mounting: The finished towel warmer is installed in the bathroom or another location where it will be used. The installation should be done professionally and securely.

-

Finishing and Decoration: Depending on the design and interior style, towel warmers can be decorated with decorative elements, coated with corrosion-resistant finishes, or have design features like integrated shelves or hooks.

-

Quality Control: Similar to other metal products, quality control plays a crucial role in ensuring the reliability and safety of towel warmers.

-

Custom Design: Custom manufacturing allows for the creation of a towel warmer that meets unique needs and complements the interior style.

Custom towel warmer manufacturing provides the opportunity to create individual and functional bathroom elements that add comfort and convenience to daily life. These products can also serve as decorative elements, enhancing the overall interior design.