Engineering systems maintenance

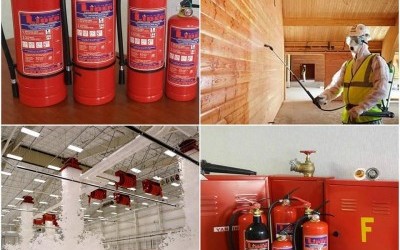

Engineering system maintenance is the process of regularly caring for, inspecting, and performing technical upkeep on various engineering systems, equipment, and devices. The purpose of this process is to ensure the normal operation of systems, extend their lifespan, and minimize the risk of breakdowns and failures. Here are some key aspects of engineering system maintenance:

-

Maintenance Plan: A maintenance plan is developed, outlining the schedule and list of tasks to be performed. The plan typically takes into account manufacturers&single_quot; recommendations and technical maintenance guidelines.

-

Regular Checks and Inspections: Engineering systems and equipment undergo regular checks and inspections to identify potential issues and wear and tear. This allows for prompt action to address them.

-

Technical Servicing: This involves conducting routine technical tasks such as filter replacement, bearing lubrication, equipment tuning, and other procedures to maintain their operational condition.

-

Repair and Replacement: When necessary, repair work is carried out, and components or parts of engineering systems are replaced to restore their functionality.

-

Upgrade and Modernization: In some cases, systems are subject to modernization and upgrading to meet contemporary technological requirements and standards.

-

Spare Parts and Materials: Maintenance includes managing spare parts and materials to ensure the availability of resources needed for repairs and replacements.

-

Safety: Safety standards are adhered to during system maintenance, and specialists use appropriate equipment and protective measures.

Engineering system maintenance is crucial to ensuring the reliable operation of various infrastructure systems, industrial equipment, buildings, and structures. It helps prevent accidents, reduce operational costs, and ensures the long-term functionality of technical systems.