Fabrication of doors and windows

Custom window and door manufacturing is the process of creating individual and high-quality window and door structures that meet the unique requirements of clients and the characteristics of their spaces. Here are several key aspects of this process:

-

Design and Consultation: The process begins with a consultation with the client to discuss preferences, requirements, and the design of windows and doors. Style, dimensions, color palette, types of glass, and hardware are determined.

-

Material Selection: Choosing suitable materials plays a crucial role. This may include various types of wood, aluminum, glass, and other materials that provide both durability and aesthetics.

-

Manufacturing and Processing: After selecting materials, window and door structures are manufactured using specialized technologies and equipment. Materials are processed to create the desired shapes and textures.

-

Installation and Assembly: Once windows and doors are ready, they are installed in the designated openings. Hardware is installed, and a thorough check is performed to ensure proper installation.

-

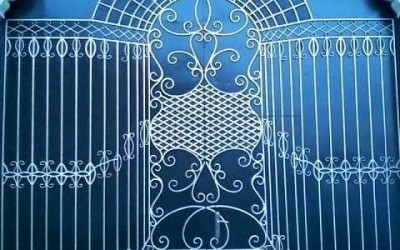

Finishing and Decoration: Depending on the design, windows and doors can be finished, such as adding decorative elements, carving, mosaic, or coatings for protection and embellishment.

-

Insulation: A crucial aspect of window and door manufacturing is ensuring proper thermal and sound insulation to enhance interior comfort.

-

Warranty and Maintenance: After installation, manufacturers typically provide a warranty, technical support, and maintenance recommendations.

Custom window and door manufacturing allows for the creation of personalized and functional elements for both interior and exterior spaces, combining style, security, and energy efficiency. These structures enhance the appearance of a home and provide comfort and safety for its occupants.